Portada >

Noticias corporativas >

Designing a Crushing & Screening Plant – Part III. Final Cone Crushing Stage

Portada >

Noticias corporativas >

Designing a Crushing & Screening Plant – Part III. Final Cone Crushing Stage

2020.11.13

2020.11.13

We are now focusing on the final part of the crushing and screening plant, this is where most of the products are produced. These products are often produced to meet specific quality demands such as fraction accuracy, gradation curve, shape, and strength. How the stage is designed and operated will have a direct effect on these parameters, so it is important that the quality demands are established before the stage design is started.

In addition to this there are many fractions produced in the final stage. Often some are in more demands than others so producing a good mix between the different products will also be important.

For the final crushing stage there are more design options than in previous stages. It is important to understand what can be done but also what both the pros and cons are with certain solutions. In this paper we will discuss how a final stage can be designed to make the desired products without making the process overly complicated.

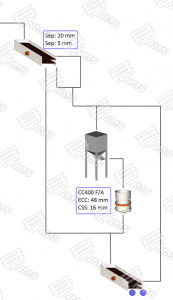

One of the first decision to make in the design process is where to position the crusher: Should the material sent to the final crushing stage be screened to produce final products before it is crushed. If there are no shape demands this could be done. Another aspect of screening before crushing is extraction of fines. It is especially important to run the crusher in the final stage without fines in the feed. So, if there is fines in the feed the best practice is to remove them before the crusher, see Figure 1.

Figure 1. Start the final stage by removing the fines. Fines should not be fed to the crusher, instead it can be bypassed the stage and fed directly to final screens.

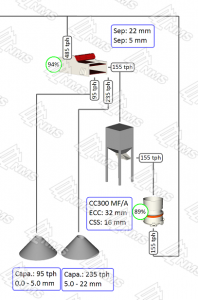

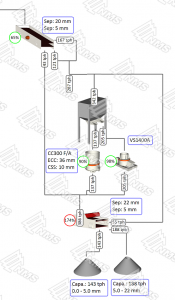

The positioning of the screens before the crusher has one main downside, shape of final products. As discussed in the paper about cone crusher configuration the best particle shape is found at the same size as the crusher setting. If the material is screened before the final crusher the crusher setting producing most of the material is substantially larger than the product size. In Figure 2, 54% of the secondary crusher product is smaller than 22 mm and will therefore go direct to the final products. Even though it is blended with 46% tertiary crushed material it will not be enough to produce final products with good shape.

Figure 2. Pre crusher screening of final products. Only the oversize is crushed in the final crusher. (For simplicity, the screening is only done into 0-5 mm and 5-22 mm. In a real application more screens would be utilized.)

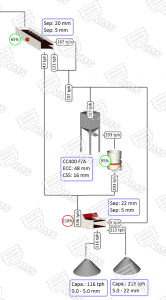

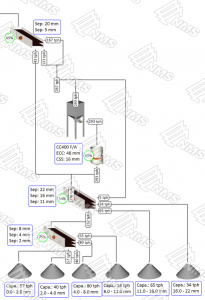

If the plant instead is designed as in Figure 3 all the final product will have been crushed at least once in the final crusher. This will produce a far better shape in the final products and especially in the sizes around 16 mm since they are sized near the same size as the final crusher CSS.

Further on in the comparison we see that the production of 0-5 mm material increases from 95 tph to 116 tph. This will be an issue for those aggregates producers that experience a low demand for 0-5 mm products. Especially if it is put in relation with the amount of 5-22 mm that is produced, the ratio goes from 40% to 54%.

Figure 3 Post crusher screening of final products. All material larger than 5 mm is sent to the final crusher. (For simplicity, the screening is only done into 0-5 mm and 5-22 mm. In a real application more screens would be utilized.)

The other aspect of where to position the final crusher is cost. Screening before the crusher will remove a significant amount of material that otherwise would be fed to the crusher. The demand for crusher capacity will therefore be a lot smaller and hence a smaller crusher can be selected, compare Figure 2 and Figure 3. As seen in the two figures the crusher size has dropped from a CC400 to a CC300. The weight of these crushers are 32 tons vs 20 tons so there is a significant difference in size. The question on final product shape is therefore crucial to answer before the process design starts.

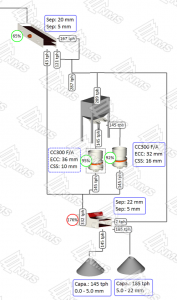

The process in Figure 3 required a final crusher of significant size. An alternative to this is to utilize two smaller crushers. This will of course need a bigger investment, but it has some interesting advantages that could lower production cost, improve product quality and improve plant flexibility. When utilizing two final crushers it is of course possible to run the two crusher at different settings which will have a positive effect on product shape, see Figure 4. The size interval with good shape will be wider if the two crusher products are mixed before screening.

Figure 4. Final crushing stage with two cone crushers in parallel. As seen in the figure they are running at different CSS to widen the interval where good particle shape is produced.

A more interesting aspect of this setup is that it will allow you to fine tune the process by combining crusher settings. Since the crushers has the possibility to change eccentric throw, and thereby change capacity. It is possible to do a lot of tuning without sacrificing the possibility to run both crushers choke fed. Another advantage of two crushers in parallel is that it will be possible to continue operation at reduced capacity while one of the crushers is down for maintenance. Keeping the process in operation will increase the plant availability and reduce the need for total plant shutdowns, this will help to lower production cost.

While on the subject on configuring the plant with parallel crushers there is also the possibility to have a cone crusher in parallel with a VSI crusher. This will also improve the particle shape but the down side is that it will not be possible to change the production as mush as with two cone crushers since the VSI does not have the same possibility to change output gradation as the cone crusher.

Figure 5. Final crushing stage with a cone crusher in parallel with a VSI crusher. This setup will further improve material shape but not be as flexible when it comes to changes in production.

So far we have not focused on the screening of the crusher output into final products. For an aggregate plant this is a major challenge and must be done with accuracy so that the sellable products are inside their specifications on amount of oversize and undersize. In some cases, many narrow fractions will be made and in those cases it will be very hard to achieve the needed cleanness in all fractions, it can always be expected that at least one fraction must be sacrificed.

Figure 6. Final screening, two screens with three decks are used to produce six products.

As mentioned before flexibility in production has a value for some plants where the demand changes over time. One additional way to address this is to introduce the possibility to send finished products back to the crusher, see Figure 7. In some sense this might be viewed as a waste since finished products are destroyed but there is often a limit (both economically and in terms of storage space) how much material that can be stored.

Figure 7. Same plant as in Figure 6 with the addition of the possibility to re-crush the two coarsest products.

The design of the final crushing stage is often the most complicated and where most of the creativity is needed. Many aspects of the production must be included in the design and there are often several different production scenarios that needs to be covered. At first glance it might look easy to add flexibility but changing the production rate in different places will often have secondary effects that must be addressed. In order to predict this a simulation software is needed. Just to make the illustration for this paper required numerous simulations to be made and still one can spot possibilities for changes that would make the process even better.

We will end with a final recommendation: If the design of the final stage is part of a larger design project. Go back to previous stages and continue to tune the process. Making all the parts of the plant work well together often have a significant effect on the equipment selection and setup. Expect to find at least one machine where you will be able to select a one step smaller machine.